Installation and commissioning

Send project managers and technicians with rich practical experience to the site to carry out installation and commissioning with customers in strict accordance with the product manual

Explore More

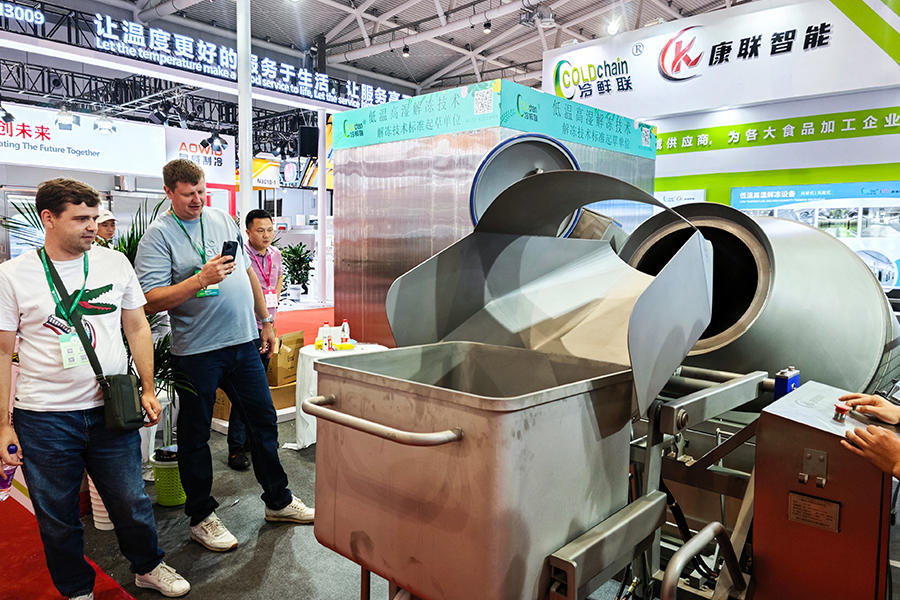

The main equipment includes: low temperature and high humidity thawing equipment, cooling equipment, quick freezing equipment, tumbling and pickling equipment, smoking and aging equipment and other meat processing machinery.

0+

0

0+

0+

In-depth use scenarios in each industry to provide appropriate solutions

Send project managers and technicians with rich practical experience to the site to carry out installation and commissioning with customers in strict accordance with the product manual

Explore More

Equipment operation and maintenance training for operators. The training content includes: equipment operation, inspection and daily mechanical and electrical maintenance, etc.

Explore More

We have regular telephone return visits with each of our customers to understand whether the cooling effect of the equipment meets their needs

Explore More

The main equipment includes: low temperature and high humidity thawing equipment, cooling equipment, quick freezing equipment, tumbling and marinating equipment, smoking and aging equipment and other meat processing machinery

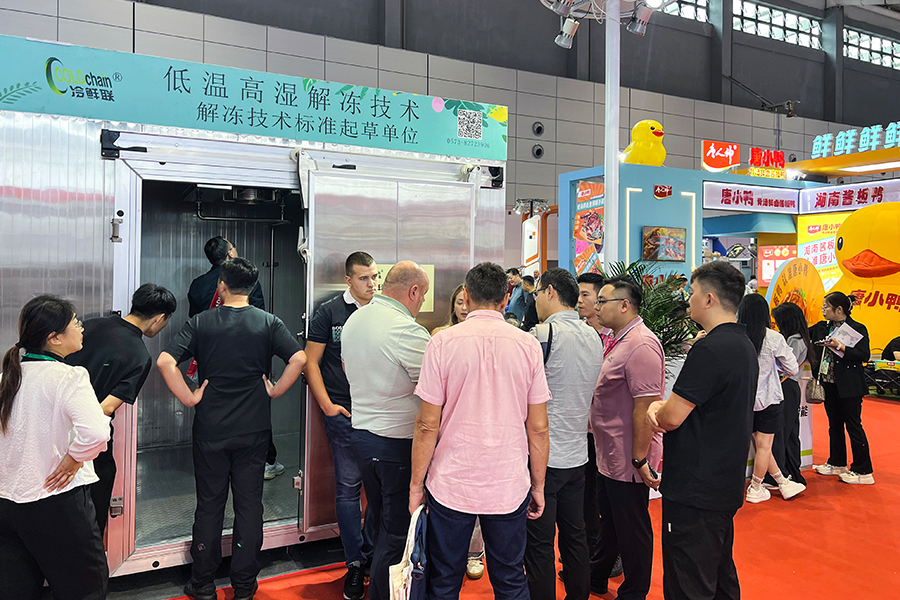

The 22nd China International Meat Industry Exhibition was successfully concluded from September 10 to 12, 2024. This exhibition is a grand event in the meat industry, bringing together well-known companies and professionals from all over the world.